"This particular boat is also very simple

to build, and represents an excellent model for the beginner. " Reuel

Parker

|

|

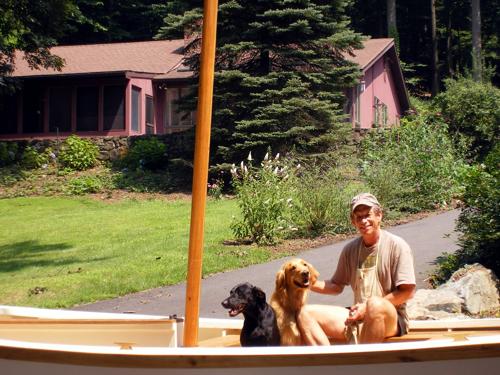

Photo: Andrew Slavinskas

The sharpie design is believed to have originated along the Long Island Sound in the 1800's as a workboat in the oyster fishery. Sharpies are long, narrow sailboats with flat bottoms, extremely shallow draft, centerboards and straight, flaring sides. They are noted for being relatively easy to build, very fast, stable and had the ability to carry a lot of cargo. This particular design is a half scale model of a workboat used in the Great Lakes.

VIKA - A Scottish girl's name meaning "from the creek." Since my workshop is just feet away from Rockaway Creek and we recently vacationed in Scotland, the name seems appropriate. (and it only has 4 easy to paint letters!)

The Crew: Steve Brookman: Novice Boatbuilder, Wife: Susan: Novice Sailmaker, Dogs: Schooner and Dory, loyal companions and consultants.

Background: I've been sailing most of my life, even spent several years as a live aboard. When we moved to NJ in 2006, we moved to a beautiful part in the hilly western part, a good drive from the "shore" as the ocean is called in NJ. There are 2 reservoirs and several lakes nearby. That and the current economic situation made small boats a nice option. I had never really thought seriously about building one, but I caught the building bug after reading about sharpies in Wooden Boat Magazine and Reuel Parker's Sharpie Book.

Not having a great amount of woodworking skill or knowledge, or even tools for that matter, it has been, and is, a learning experience. I can appreciate the value of apprenticeship, shop class, trade schools, at virtually every step of the building process, as I stare, scratch, flip through one of the many reference books, or search the web, trying to figure out what is the next step and how best to do it.

That being said, I must confess to now being a boat building addict. While this sharpie is just out of the shop I've already ordered plans for a next boat(s). Now with some better tools and a little experience I can envision how the next one will come out, and the next....

Summer 2007: Peace Canoe-Before there was a Sharpie project I built the Peace Canoe as a warm up. I finished it in the fall of 2007, and finally launched it June 2009.

Wood-Finding wood for this project took many phone calls, internet searches, and visits to lumber yards. I eventually stumbled upon a small sawmill (Middle Valley Lumber) in Califon, NJ just 6 miles from our house! It has a wide assortment of local woods, some suitable for boat building, including white oak, ash and black locust. I did find Douglas Fir in the local lumberyards.

Frames, floors, keelson: white oak

Bottom: 1/2" marine ply, sides: 3/8" marine ply, deck: 1/4" marine ply

Stem, apron, CB posts, thwarts, wale/sheerstrake, cleats : black locust

Masts, logs, CB, rudder: douglas fir (CB & rudder sheathed in 1/4" ply) masts have 1" spruce laminated between 2" DF

Tiller: ash Sculling oar: ash and spruce

The 19' Ohio Sharpie

as drawn by Reuel Parker

Sharpie Progress

2010

Summer

Spring

Winter

2009

November

October

September

August

July

June

May

April

March

January-February

2008

December

November

October

September

August

July

Comments, suggestions, questions?

Thinking of building your own Sharpie or have a suggestion on how it should really be done, let me know.

Modeling, Not Just for Kids

by Me (Steve Brookman)

An article in the April 2010 Mainsheet, Newsletter of the Delaware River Chapter of the Traditional Small Craft Association

For more information on the

Delaware River Tuckups

visit: Tuckups.com

Starting to put the pieces together. This is exciting and a bit unnerving as there is a level of permanence now. Parts will be screwed, bolted, bunged and visible! I'm keeping my fingers crossed that everything fits, works, and maybe even floats. Sailing is still months away, but I'm already scratching my head about the rigging.

Sheerstrakes/wales added. Resawed and scarfed my remaining black locust plank. The resawing was just about the limit of my woodworking ability, the scarfs came out ok. The actual wrestling and fitting them in place was not as difficult as I had imagined, but one side did complain more than the other.

Cleats out of Black Locust seemed to fit the boat.

While the hull is no where near as fair as I'd like, I'm finally accepting it and moving on. This is my first real build and have I've left lots of room for improvement for next one.

I hadn't used that leather briefcase in years. I'm hoping I'll get better use out of it as mast (and soon to be, oar) leathers.

Last view of the interior before the thwarts and stern sheets get put on. At least 3 coats of Interlux over epoxy on all surfaces. There will not be any permanently sealed areas, although getting to the niches in the stern will be a challenge. Rigid foam glued under the deck and in forepeak.

Rudder and CB primed with 2 part epoxy paint. Final paint next and then the fun begins: getting the board fitted in the trunk. Wrestling this CB around makes one think about how large the next boat should be!

(Mouse over to see almost finished rudder)

Putting the pieces together, hopefully not prematurely. Stern sheets, screwed, bunged and tung oiled.

Centerboard installed, only had to take it out and recut/refit it a couple of times. I rigged a double purchase and a cam cleat to get the thing back up. I made up a batch of tallow, ala Pete Culler, to grease it (and had to train the dogs not to lick it!)

The centerboard was faired, and fitted with 32# of lead. I was just about to melt and pour when I realized that the lead ingots were very close to the thickness of the board so I opted to trim them and epoxy them in place.

The board was then covered with 1/4" ply and dry fitted into the CB slot. Good idea there as the slot has shrunk some! Trimmed about 3/4" off the length of the board.

Faired the edges, sealed it with cloth and several coats of epoxy (doubling + the bottom and forward edge.)

Rudder planed, covered with 1/4" ply, xynole cloth and epoxied. Tiller carved and pintle straps chiseled.

Laminated some black locust to make a cap for the top of the transom.

Wasn't happy with the hull, so gave it the pox, with another coat of thickened epoxy. Should have done that before flipping her over.

|

|

|---|

January-February 2009

One cold winter here in NJ! Since not much is getting done on the real boat, I decided to remake the model of it and see how a "dog-house" would look. Also changed the paint scheme and used black locust for thwarts and trim as I plan to do on the real thing, one of these days.

Not much progress on the boat, not only was it cold, even for December, I had to make 88 awards for a trail run in January that I direct. I did get the CB halves put on. Hoping to make some good progress in 2009. While I can dream of sailing it's too soon to know if it will happen this year.

Decks, CB posts and mast steps in. Making a mess but starting to get a feel for what she'll look like.

CB trunk halves, clothed, epoxied and painted with Tile Clad

Used the grips from a broken plane to make this long board sander. Wish I had made this earlier.

Interior epoxied, 2 coats of paint, side frames and deck carlins added.

Still carving centerboard.

Bottom painted, not w/real bottom paint since she won't live on a mooring. Next, get a crew to flip her.

Flipped! No crew so rigged a block & tackle and recruited wife, again.

September 2008

Plumbed the loft, and my workshop. Used up the extra sheet rock that had been occupying valuable shop floor space and made a small office in a back corner. As long as I was tearing and building stuff, I used some white oak to fashion a more usable workbench. Now onto the fun stuff. Susan's Dad showed up and we cut the centerboard slot, did some fairing, applied one layer of xynole polyester cloth and 3 coats of epoxy.

Susan's glass studio, above the boat shop.

(mouse over shows a before shot)

A quick workbench, and a old vise from a yard sale.

Small office area in back of shop.

Moby Boat! Epoxied, primed and about ready to be flipped.

Planked, well, clamped anyway. Reuel has you glue the side panels to the stem and then mount this big "V" of plywood on the frames. Not a solo operation, thankfully I have a strong wife.

Necessary side track: you get rough sawn lumber you need a planer. Since it was a bench planer I had to build a base for it. The soft cast is for an Achilles issue. Amazing how much more time you have for stuff when you're not running 50 miles per week.

No matter how long I work or how boring it gets, loyal Dory guards the shop.

Planking trimmed, chine logs and keelson attached, bottoms up next!

Bottom's up and on, with some 5200, epoxy and bronze ring nails. Stem attached also. Next up, ease the bottom edge, cut slot for CB, then apply cloth and 3 coats of epoxy. But before that there is a loft that needs plumbing. And since I'm tearing into things, seems as good a time as any to organize this workshop, enclose an office area and build a real workbench. Don't think the boat will go anywhere in the meantime.

Masts, logs, keelson, some ripped, some scarfed

Rudder and Centerboard (DF) in the rough, CB posts, stem and apron (Black Locust)

Strongback w/frames, we're finally building a boat! I would soon discover that the frames needed more bracing and that white oak would be more suitable than the select pine that I started with.